The Dierre Group, leader in the design and production of structural aluminium profiles, protections for automatic machines, conveyor belts and linear modules, will be present at the 24th edition of IPACK IMA, the international exhibition of food and non-food processing and packing, to be held at Fiera Milano, Rho from 29 May to 1 June 2018. The Fiorano group will exhibit the latest technological innovations dedicated to the SAFETY and MOTION industrial sectors in Hall 6, Stand F37/G38.

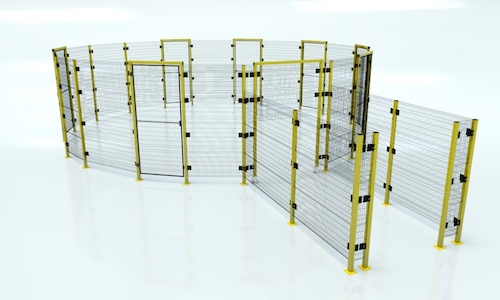

The Dierre Group’s wide range includes perimeter and modular safety guards Eco-Line and Fast-Line featuring a vast possibility for customization and compliance with the ISO/FDIS 14120:2015 standard on safety. The Eco-Line guards are also UNI EN ISO 14120:2015 certified Point 5.18 Climbing. The Fast-Line guards have a patented system for counterbalanced vertical sliding doors.

The Group’s extensive portfolio of products dedicated to SAFETY also includes modular perimeter guards ULTRA and PRO made from sheet metal and the result of the synergistic experience between Dierre and Sintesi, a company that has been part of the Dierre Group since 2017. To guarantee total safety, the guards ULTRA and PRO comply with standards EN 14120 and EN 13857 concerning prevention of accidents, health and safety of workers.

Sturdiness and aesthetics make the Dierre safety guard a distinctive element in the design of systems and production cells. The careful study of basic modules, the integration of window and door systems, allow an easy and quick installation and transform the guard into a real “tailor-made” cabin, customized according to the Customer’s requests.

The MOTION Division, specialized in the design and construction of linear guides will exhibit a wide range of its production models on the stand that boasts over 70 standard models differentiated by size, moving and sliding and the brand new telescopic axis with carbon fibre body; customized technological solutions among the most advanced, designed to facilitate and speed up production processes in industrial automation.

The conveyor belts with central motorization, in the three fixed widths 100mm/160mm/200mm are designed and manufactured by the CONVEYOR Division, within the Group.

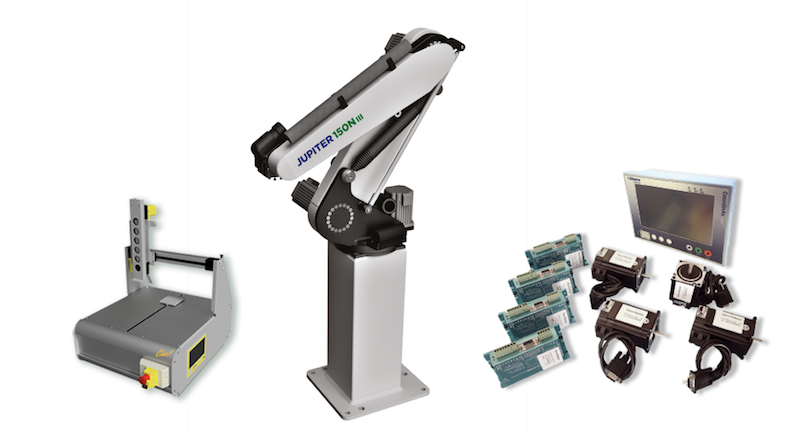

And not only, the ROBOTICS Division within the Dierre Group is able to offer highly specialized robotic systems with applications in multiple industrial fields and with direct control over production, thanks to the in-house development of all mechanical components and software.

Among the most innovative products, the new collaborative, safe, reliable and versatile desktop computer Ciao!. A real help in daily work. The collaborative desktop robot Ciao! is equipped with torque-controlled motors and guaranteed by Dierre Robotics; if it comes across an obstacle, it stops instantly. No need for training courses and no maintenance is required; just one power socket and it works in a moment.

Another leading light is the JUPITER 150NIII anthropomorphic robot, which represents the third generation of anthropomorphic robots designed by. A constructive improvement on the previous NI and NII versions with the distinctive construction in aluminium alloy and powder-coated steel. Allows easy and intuitive programming and is adaptable to any production need where precision and high accelerations are essential requirements. The management of joint movements and Cartesian kinematics is entrusted to the CoordinAx, motion system, designed in-house by Dierre Robotics.

The Dierre Group puts itself forward as the sole interlocutor for the technological solutions you are looking for, complying perfectly with the guidelines that contribute to the evolution towards Industry 4.0

We are waiting for you at Ipack Ima where our highly qualified staff will be available to customers and visitors to our stand to personally illustrate the features of the wide range of products developed and built by the Dierre Group, and the technical service dedicated to customizing solutions.