The Dierre Group will present an absolute preview of the new ULTRA and PRO modular perimeter safety guards made of sheet metal and the result of the synergistic experience between Dierre and Sintesi, a company that has been part of the Dierre Group since 2017. Stability and aesthetics make safety guards the distinctive element in the design of production plants and cells.

The careful study of the basic modules, the integration of windows and door systems, allow an easy and fast installation and transform the guards into a real “tailor-made” cabin, customized according to the Customer’s requirements.

To guarantee total safety, the ULTRA and PRO guards comply with the EN 14120 and EN 13587 standards on the prevention of accidents, and health and safety of workers.

The Dierre Group’s wide range also includes the perimeter and modular safety guards Eco-Line and Fast-Line characterized by many opportunities for customization and compliance with the ISO/FDIS 14120: 2015 standard on safety.

The Eco-Line safety guards are certified to UNI EN ISO 14120:2015 Point 5.18 Climbing.

The Fast-Line safety guards have a patented system for counterbalanced vertical sliding doors.

The linear guides made by the Motion division, are accurate, reliable and customizable according to the customer’s needs.

A wide range of products available from the catalogue:

• Linear guides with inner runner

• Screw driven linear guides

• Linear guides with internal wheels

• “Easy Line” series linear guides with external runners and wheels

• Vertical guides

• Monorail linear guides

Conveyor belts with central drive, in three fixed widths 100mm/160mm/200mm designed by our Conveyor department.

Dierre Robotics, the industrial division specializing in production processes and the development of robotic solutions for the smart factory that takes full advantage of industry 4.0, offers the new collaborative, safe, reliable and versatile desktop robot Ciao! a real daily help at work. The Ciao! collaborative desktop robot is equipped with torque motors controlled and guaranteed by Dierre Robotics; if it comes across an obstacle it stops instantly. No need for training courses and no maintenance is required; just a power socket and it starts working.

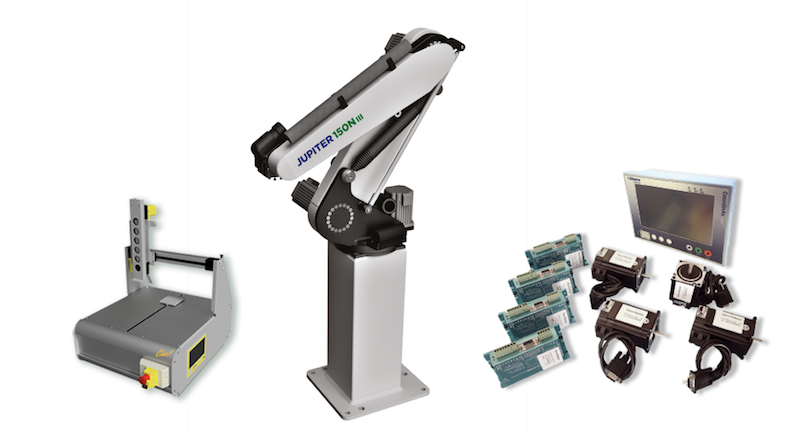

JUPITER 150NIII, is the third generation of anthropomorphic robots designed by Dierre Robotics. A constructive improvement of the previous NI and NII versions with the characteristic construction in aluminium alloy and powder-coated steel. It allows for an easy and intuitive programming and is adaptable to any production requirement where precision and high accelerations are essential requirements. The management of joint movements and Cartesian kinematics is entrusted to the CoordinAx motion system, designed in-house by Dierre Robotics. Visit the new Dierre Robotics website in 4 languages and with modern and intuitive graphics, smart showcase for the wide range of products offered by the Robotics division.

What’s the next appointment?

HANNOVER Germany – 23/27 April 2018

Dierre Hall 016 Booth D03 – We are waiting for you!